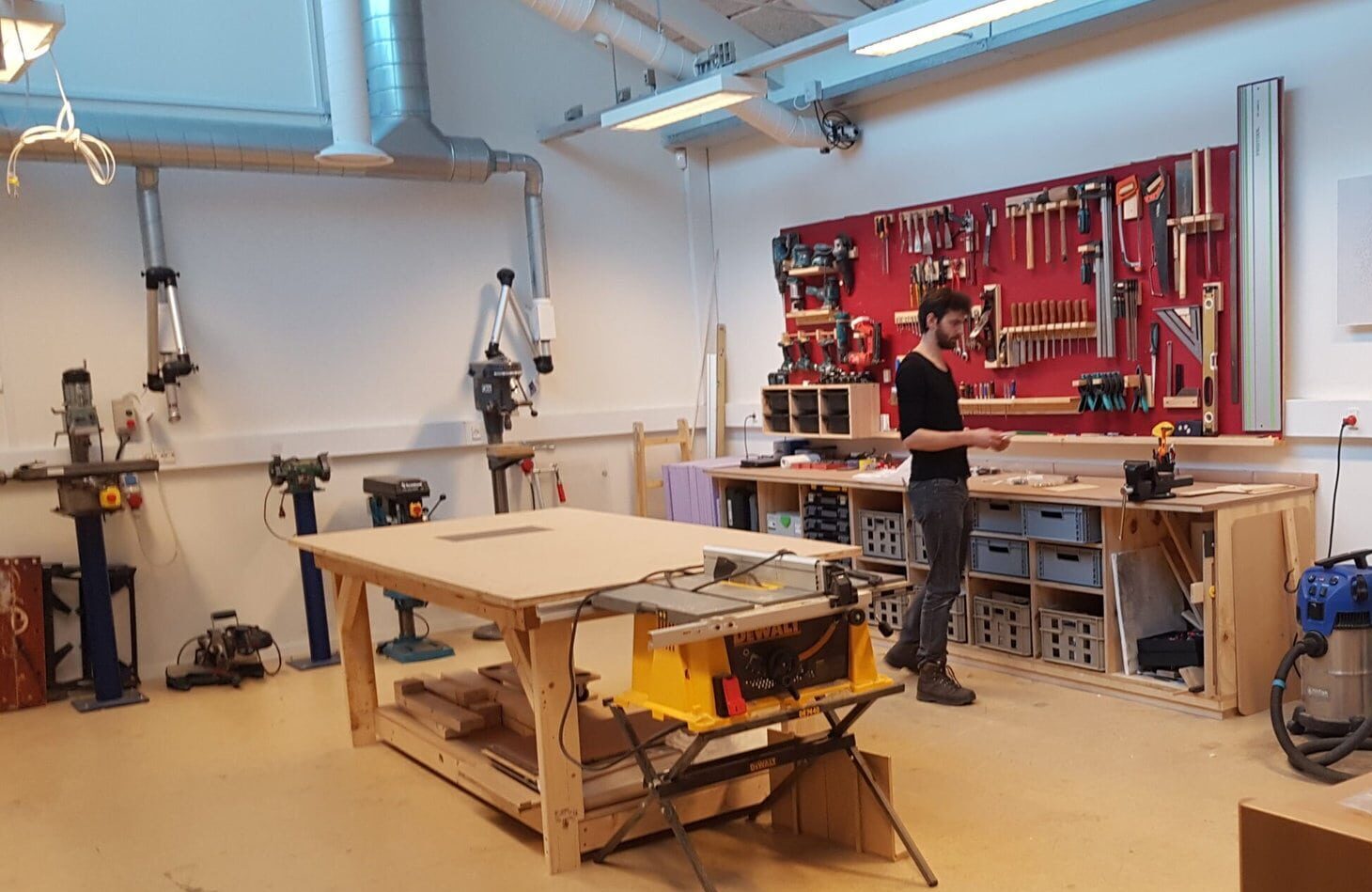

Workshops

Build your prototypes in Sound Hubs many workshops

Use our workshops to construct mechanical parts, assemble electrical modules, build prototypes and do functional tests.

No need to bring your own tools, we have hand tools. And you can even paint here; a painting cabinet with exhaust is available also for your use.

Electronics

Fixing a few critical parts yourselves? A solder station with exhaust is available for you.

Electronic workshop

Wood

In our workshop area you can make use of both a bandsaw and a portable saw - or let us match you with partners, who can do it for you.

Wood workshop

Metal

In need of an overhead mill for metal (or plastic) - a bench grinder or drill press? We have it all available in our workshop.

Metal workshop

3D print

Considering using our Ultimaker S5 for development samples? Let us assist you.

3D print

Material library

Samples of speaker units and connectors including a network of industry partners with interest to deliver components and evaluation boards on special terms; might become handy.

Samples

Get in touch

Are you interested in joining Sound Hub and making use of workshops and other test facilities?